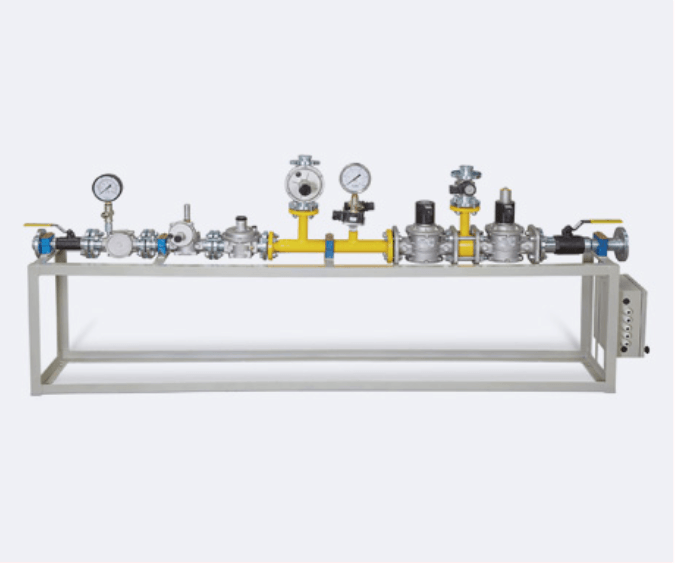

MADAS GAS TRAINS

Innovative Automation Private Limited manufactures Gas Trains in Standard and Custom Configuration. The Gas Trains is the essential Part of Gas Burner Safety, we manufacture it on lines of:

- NFPA 85 for Burner & Boiler Safety Regulations.

- NFPA 86 for ovens & furnaces.

- Also the European Gas Regulation standard EN 746-2.

- Pre-Piped and Pre-Tested Gas Trains are made to be as easy as Plug & Play. Time & effort saving Gas Trains are extremely OEM friendly.

- IAPL manufactured Gas Trains are available for Gaseous Fuels like Natural Gas, LPG, Propane, Biogas.

- Inlet Connections from DN15 to DN150.

- Outlet Connections from DN15 to DN300, Flow range upto 5000 Nm3/hr.

- Inlet Pressure ratings from 0.5 Bar to 6 Bar.

- Gas Train Design and Assembly:

- Inlet and outlet isolation valve

- Inlet and outlet pressure gauge

- Gas Filter

- Slam shut off valve

- Gas pressure regulator

- Safety relief valve

- Low & high-pressure switch

- Madas Solenoid Valve (First & second Safety solenoid valve)

- Vent valve normally open

Most of the Madas components are ATEX approved for installation in Zone 2 & 22, Group II 3G & II 3D.

Various configurations as per Combustion System Requirement with Elgas Gas Flowmeter, valve proving system, gas flow control valve, prewired junction box optional.

IAPL has in-house State-of-the-art Gas Train Testing Laboratory capable of measuring the flow upto 2500 Nm3/hr.

Each manufactured Gas Train is subjected to over 40 safety & performance tests for internal and external leakages, flow rates, set points.

Customer or 3rd party inspection can also be provided on request.

SolidWorks 3D modelling software for design & manufacturing.

Onsite installation, commissioning services & Annual Maintenance Contract (AMC) for all Madas Gas Components.

More than 2500 gas trains are installed across the country and performing satisfactorily at some of the prestigious organizations.

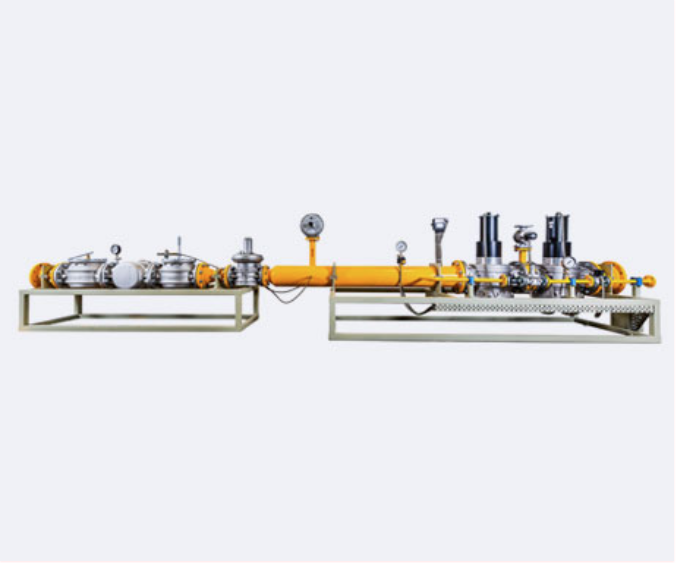

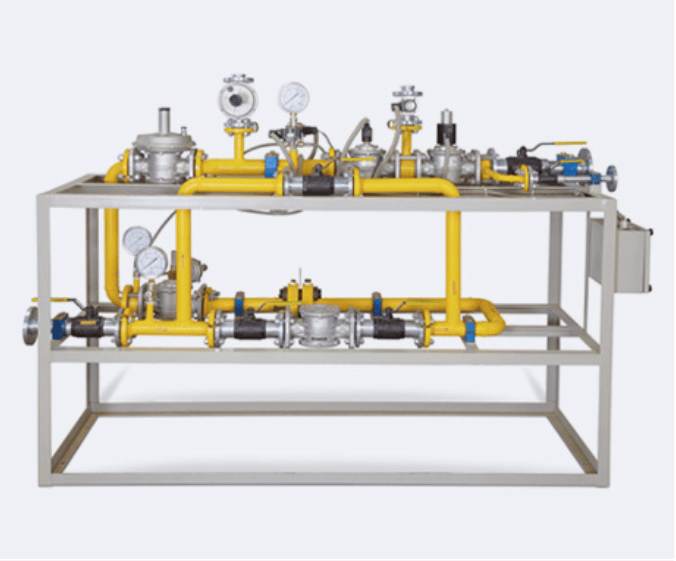

Dual Gas Trains

- Riding on unfathomable volumes of industrial expertise, we are engaged in offering Dual Fuel Gas Train. A dual fuel gas train is equipment that is alternatively gas-fired and oil-fired.

- This mighty yet compact beast comprises of 5 lines namely: Combustion Airline, Oil line, Main Gas line, Pilot Gas line, Atomization Airline which are mounted on one integrated base frame along with piping connection up to the burner.

- Change-over selection from gas to oil is provided and all the electrical components are pre-wired on Common Junction Box.DN65DN300: Flanged as per ISO 7005 (PN16) Or ANSI B16.5

- This makes the user's job hassle-free and is limited to simply connect the inlet connections and start operation.

- Dual Fuel Gas Train Components:

- Gas Line = Manual Isolation Valves, Filter, Slam Shut off valve, Pressure Regulator, Pressure Relief Valve, Pressure Gauges, Pressure Switches and Solenoid Valves.

- Oil Line = Manual Isolation Valves, Strainer, Pressure Regulator, Pressure Gauges, Pressure Switches and Solenoid Valves.

Sizes:

- Inlet Connection: Gas: DN15 to DN200

- Oil: DN15 to DN50

- Outlet Connection: Gas: DN15 to DN300

- Oil: DN15 to DN40

- Flow Capacities: Gas = Up to 5000 Nm3/hr Natural Gas

- Oil = Up to 14000 LPH

- Inlet & Outlet Pressure Capacities: Gas = Inlet 0.5 to 10 bar

- Outlet : 0.1 to 4 bar

- Oil = Inlet 5 to 10 bar

- Outlet : 1 to 7 bar